Exploring Octagonal Aluminum Tubes: Applications, Benefits, and UK Availability

Introduction to Octagonal Aluminum Tubes

Imagine a world where structural components are not only strong and durable but also uniquely shaped to optimize performance. Enter the octagonal aluminum tube, a marvel of modern engineering that combines the lightweight, corrosion-resistant properties of aluminum with the geometric advantages of an octagonal design. These tubes are increasingly becoming a staple in diverse industries, from construction and manufacturing to energy and recreation, due to their versatility and efficiency in various applications.

What makes octagonal aluminum tubes stand out is their ability to distribute loads more evenly, enhancing structural integrity without adding unnecessary weight. This is particularly beneficial in construction, where they are used in frameworks and architectural features, or in the automotive sector, where reducing weight can significantly improve fuel efficiency. Moreover, their aesthetic appeal makes them a popular choice for projects that require both form and function. As we delve deeper into the specifics of octagonal aluminum tubes, you'll discover how their unique properties and applications are revolutionizing industries worldwide.

Understanding Octagonal Aluminum Tubes

When you think of aluminum tubing, the typical round or square shapes might come to mind. However, the octagonal aluminum tube offers unique advantages that set it apart from conventional profiles. The octagonal shape is not just an aesthetic choice; it provides significant geometric benefits. With eight sides, these tubes offer enhanced rigidity and stability, distributing stress more evenly across their structure. This makes them particularly suitable for applications requiring superior load-bearing capabilities, such as in building frameworks or heavy-duty automotive components.

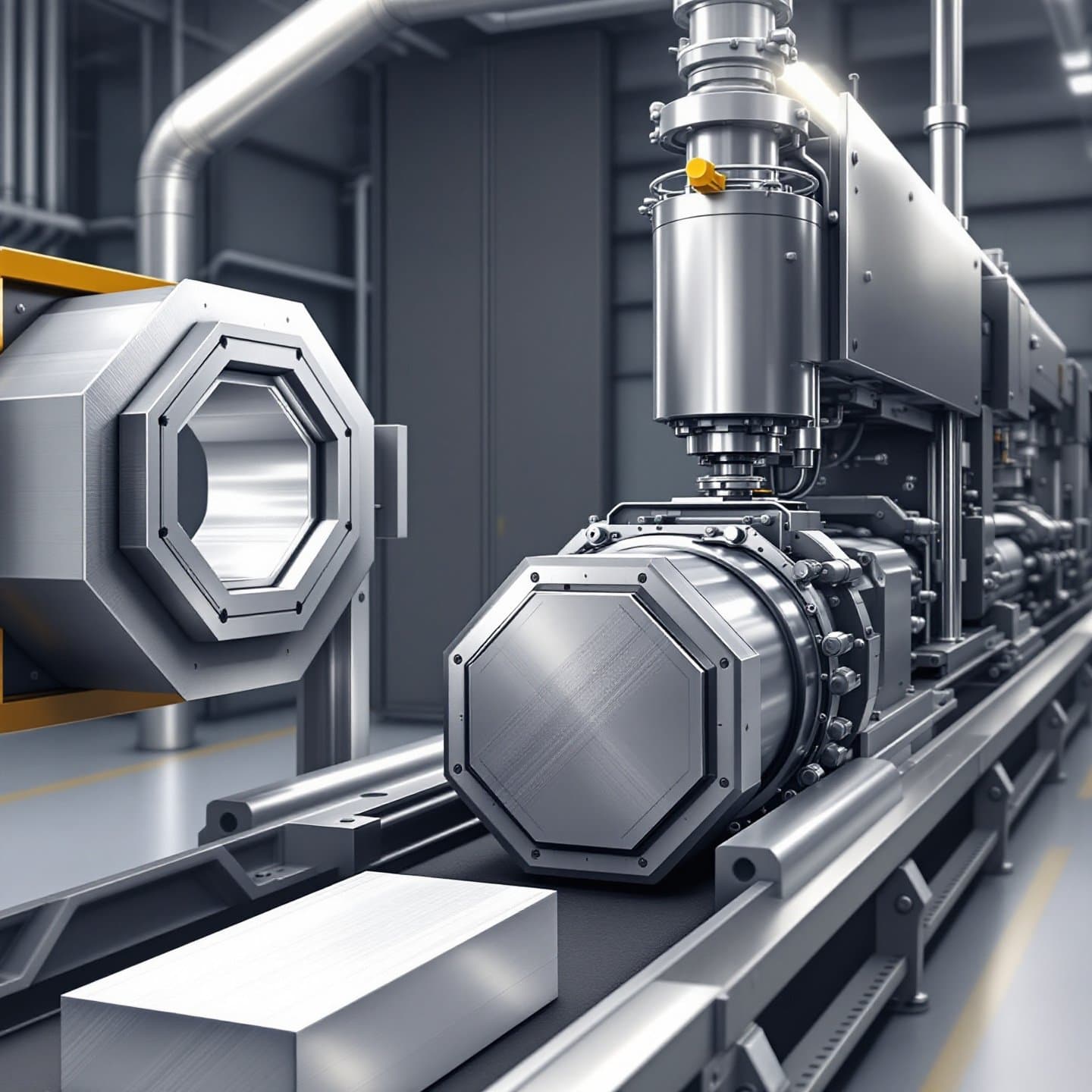

The manufacturing process of octagonal aluminum tubes involves extrusion, a technique akin to pressing toothpaste from a tube, where aluminum is forced through a die to achieve the desired shape. This process allows for precision and consistency, ensuring that each tube maintains the exact specifications needed for its application. According to IQS Directory , the extrusion process can produce intricate shapes that retain aluminum's beneficial properties, such as its excellent strength-to-weight ratio and corrosion resistance.

These properties are further enhanced by selecting the appropriate aluminum alloy, such as 6061 or 7075, known for their durability and strength. The natural corrosion resistance of aluminum makes these tubes ideal for outdoor and marine applications, where exposure to the elements is a concern. Additionally, their lightweight nature means they can be used in applications where reducing overall weight is crucial, such as in aerospace or transportation industries. By leveraging the octagonal shape benefits and the inherent aluminum tube properties, these tubes provide a versatile solution for modern engineering challenges.

Applications of Octagonal Aluminum Tubes in Diverse Industries

When you consider the versatility of octagonal aluminum tubes, you'll notice their remarkable adaptability across various sectors, particularly in the construction and automotive industries. These tubes are not just another component; they are integral to enhancing structural integrity and efficiency in a multitude of applications.

Construction Industry: Building Strong Foundations

In the construction industry, octagonal aluminum tubes are prized for their strength and lightweight properties. They are often used in structural frameworks, providing a robust backbone for buildings while minimizing the load on foundations. Imagine constructing a skyscraper with materials that are both strong and light, reducing overall construction costs and improving safety. These tubes are also employed in architectural features, where their unique shape adds aesthetic value without compromising functionality. Their corrosion resistance ensures longevity, making them ideal for outdoor applications where exposure to the elements is a concern.

Automotive Sector: Enhancing Performance and Efficiency

In the automotive world, the use of octagonal aluminum tubes extends to vehicle frames and other critical components. Their high strength-to-weight ratio is crucial in reducing vehicle weight, which directly impacts fuel efficiency and performance. For instance, using these tubes in the chassis and suspension systems can significantly enhance a vehicle's handling and durability. The octagonal shape offers additional rigidity, distributing stress more evenly and improving safety during collisions. As noted by Six Aluminium , aluminum's ease of fabrication allows for complex designs that optimize aerodynamics and aesthetics.

Headache Racks and Truck Accessories: Practical and Durable Solutions

Octagonal aluminum tubes also find applications in the design of headache racks and other truck accessories. These racks, mounted behind the cab of a truck, protect the rear window from shifting cargo. The tubes' durability and lightweight nature make them an excellent choice for these applications, ensuring that the racks can withstand the rigors of daily use without adding unnecessary weight to the vehicle. Additionally, their resistance to corrosion means they maintain their integrity and appearance over time, even when exposed to harsh weather conditions.

As we continue to explore the multifaceted uses of octagonal aluminum tubes, it's clear that their unique properties make them indispensable across various industries. Their ability to combine strength, aesthetics, and functionality ensures they remain a preferred choice for engineers and designers looking to innovate and improve upon traditional materials.

Advantages of Octagonal Aluminum Tubes

When considering materials for construction and manufacturing, the octagonal aluminum tube stands out due to its unique advantages. These tubes are not only aesthetically pleasing but also offer a range of functional benefits that make them a preferred choice in various industries. Let's explore these advantages:

- Enhanced Structural Integrity: The octagonal shape provides superior load distribution, which enhances the structural integrity of frameworks and supports. This design ensures that stress is evenly spread across the tube, reducing the risk of failure under heavy loads. This makes them ideal for applications requiring high strength and stability, such as in construction and automotive sectors.

- Aesthetic Appeal: With their distinct geometric shape, octagonal aluminum tubes add an element of modern design to any project. Whether used in architectural features or decorative installations, these tubes offer a sleek and sophisticated look that can enhance the visual appeal of structures.

- Versatility: Octagonal aluminum tubes are incredibly versatile, suitable for a wide range of applications. From building frameworks and vehicle components to recreational equipment and decorative elements, their adaptability is unmatched. This versatility is further enhanced by the ease with which aluminum can be fabricated into complex designs.

- Corrosion Resistance: Aluminum's natural resistance to corrosion ensures that these tubes maintain their integrity and appearance over time, even when exposed to harsh environments. This durability makes them a cost-effective choice for both indoor and outdoor applications.

- Lightweight Nature: Despite their strength, octagonal aluminum tubes are lightweight, reducing the overall weight of structures and vehicles. This characteristic is particularly beneficial in the automotive and aerospace industries, where reducing weight can lead to improved performance and fuel efficiency.

In summary, the advantages of octagonal aluminum tubes lie in their ability to combine structural integrity, aesthetic appeal, and versatility. These qualities make them an indispensable component in modern engineering and design, offering solutions that are both practical and visually appealing. As we move forward, these tubes continue to play a vital role in innovation across various industries.

Availability and Suppliers of Octagonal Aluminum Tubes in the UK

When it comes to sourcing octagonal aluminum tubes in the UK, understanding the market landscape is crucial for making informed purchasing decisions. The availability of these tubes is supported by a network of reputable suppliers who offer a range of options tailored to various industrial needs. Let's explore some key suppliers and considerations for UK buyers.

Key UK Suppliers

| Supplier Name | Location | Contact Information |

|---|---|---|

| Metalex | South and West England | Visit Site | +44 (0) 330 223 2653 |

| The Metal Store | UK-wide | Visit Site | 01274 875479 |

Both Metalex and The Metal Store are prominent names in the UK aluminum market, offering extensive stocks and processing services. Metalex provides a wide range of aluminum tube grades and specifications, ensuring quick delivery across their various sites. The Metal Store, known for its high-quality aluminum tubes, offers a cutting service with free and unlimited cuts to meet specific project requirements.

Considerations for UK Buyers

When purchasing octagonal aluminum tubes in the UK, buyers should consider several factors:

- Quality Standards: Ensure that the tubes meet international quality standards such as EN12020 and EN755, which guarantee the material's reliability and performance.

- Pricing: Compare prices across suppliers while considering the cost of additional services like cutting and delivery. Some suppliers offer free delivery on large orders, which can be a cost-effective option for bulk purchases.

- Lead Time: Check the lead time for delivery to ensure it aligns with your project timelines. Suppliers like The Metal Store offer a 2-to-3-day lead time, which is beneficial for urgent requirements.

In conclusion, the UK market for octagonal aluminum tubes is well-supported by reliable suppliers who provide quality products and services. By considering factors such as quality standards and pricing, buyers can make informed decisions that best suit their project needs. As you explore these options, consider reaching out to suppliers like Suqian Sunmay Aluminium for specialized requirements, leveraging their global expertise and extensive product offerings.

Conclusion: The Significance of Octagonal Aluminum Tubes

As we conclude our exploration of octagonal aluminum tubes, it is evident that these uniquely shaped components offer significant benefits across various industries. From construction to automotive, their enhanced structural integrity and aesthetic appeal make them indispensable. The ability to distribute stress evenly and their lightweight nature contribute to their growing popularity in applications where strength and efficiency are paramount.

Octagonal aluminum tubes not only provide practical solutions but also open doors to innovative designs and improved performance. Their versatility ensures they can meet the demands of modern engineering challenges, making them a go-to choice for engineers and designers worldwide. As you explore aluminum tubes further, consider the specific needs of your projects and the potential these tubes have to transform your designs.

For those seeking specialized expertise and high-quality products, Suqian Sunmay Aluminium stands out as a leader in the industry. With a commitment to excellence and a wide range of aluminum alloys and surface treatments, they cater to diverse applications with precision and innovation. Their global reach and adherence to international standards ensure that you receive products that not only meet but exceed your expectations. To discover more about their offerings and how they can support your projects, visit their official website .

Frequently Asked Questions

1. What is an octagonal aluminum tube used for?

Octagonal aluminum tubes are used in construction for frameworks, in the automotive sector for vehicle frames, and in truck accessories like headache racks due to their strength and lightweight properties.

2. How is an octagonal aluminum tube manufactured?

These tubes are manufactured using an extrusion process where aluminum is forced through a die to form the octagonal shape, ensuring precision and consistency.

3. What are the advantages of octagonal aluminum tubes?

They offer enhanced structural integrity, aesthetic appeal, and versatility. Their lightweight and corrosion-resistant nature make them ideal for various applications.

4. Where can I buy octagonal aluminum tubes in the UK?

Suppliers like Metalex and The Metal Store offer a range of octagonal aluminum tubes, providing quality products and services throughout the UK.

5. Why choose Suqian Sunmay Aluminium for aluminum tubes?

Suqian Sunmay Aluminium offers high-quality aluminum tubes with a variety of surface treatments and alloys, ensuring compliance with international standards and catering to diverse industrial needs.