What is the construction method for sandwich panel exterior walls?Don't worry, LUSEN Factory will reveal it for you!Actually,The construction method of the exterior sandwich panel mainly includes the following steps:

1. Construction Preparation

• Technical Preparation: Before construction, organize technical personnel to review the drawings, understand the design intent, and conduct design and technical briefings. Communicate with the design unit and material suppliers to resolve any issues in the drawings.

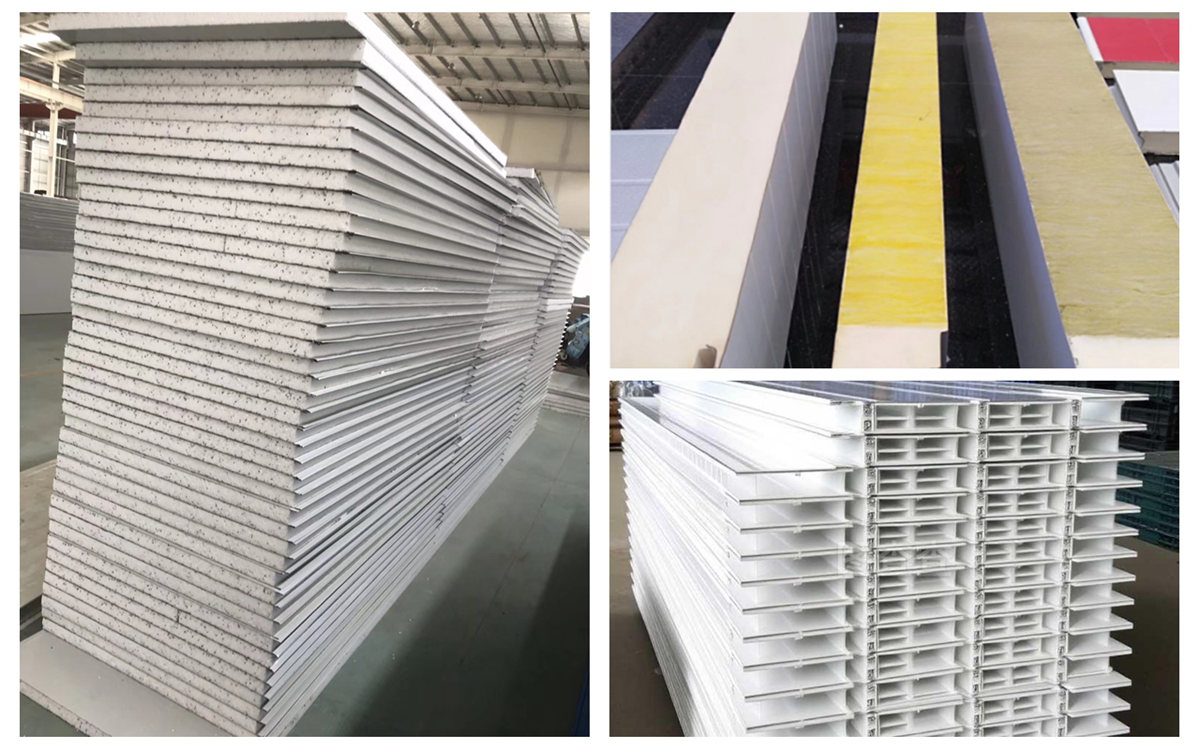

• Material Preparation: According to the design requirements, prepare raw materials such as metal sheets, insulation materials, and connectors, and conduct necessary processing treatments on the metal sheets, such as cutting and bending.

• Site Preparation: Survey the construction site to ensure that the roads meet the requirements for crane access and complete the positioning and layout work for the project.

• Panel Storage: The storage location must be flat, sturdy, clean, and ventilated. Avoid direct contact between the panels and the ground, and use sleepers to elevate them.

2. Installation of Inner Wall Panels

• Install the inner wall panels according to the construction drawings and actual site conditions. Ensure the flatness and stability of the inner panels during installation.

3. Installation of Composite Panels

• Layout: Determine the installation position of the composite panels according to the construction drawings and conduct layout work.

• Installation: Fix the manufactured sandwich composite panels to the supports or walls in sequence according to the design requirements, paying attention to maintaining the consistency of flatness and spacing between panels.

• Fixing: Use appropriate fixing methods, such as bolts or expansion screws, to ensure the stability of the composite panels.

4. Installation of Flashing Panels

• When installing flashing panels, strictly follow the drawings to ensure the lap length and sealing performance of the flashing panels.

5. Node Treatment

• Treat electrical and water nodes, component nodes, etc., to ensure the sealing and stability of the nodes.

6. Surface Treatment

• After installation, conduct surface treatments such as cleaning and painting on the exterior wall panels to enhance the corrosion resistance and aesthetics of the panels.

7. Quality Inspection

• Conduct quality inspections on the completed exterior wall panels, including appearance quality, dimensional deviations, thickness deviations, adhesion, etc., to ensure compliance with design requirements and relevant standards.

Precautions

• Safety Protection: Strictly follow safety regulations during construction and take appropriate safety measures for high-altitude operations.

• Panel Quality Inspection: Conduct quality inspections on panels before installation to avoid using panels with defects.

• Construction Environment Control: Avoid construction under adverse weather conditions and pay attention to noise and pollution control during the construction process.